Feb 13th 2025

Types of Labels and Placards for Solar Energy Installations

Installing resources such as solar labels prevents the system from undergoing severe repairs and keeps your solar grid performing at high standards. Each placard holds pertinent information necessary for proper operation and maintenance. To understand the different types of labels and placards for solar energy installations, take steps to determine what elements in the system pose a hazard or have specific usage guidelines.

Why Are Labels and Placards Crucial in Solar Installations?

Solar labels and placards mitigate severe damage and protect operators, solar companies, and the general public. First, they help installers, maintenance teams, and emergency responders easily identify system components, risks, and operational instructions. Second, they abide by the compliance guidelines set by local, state, and international safety standards.

Solar installations are high-voltage systems, and unmarked components can lead to catastrophic damage to the system and the individual. For maintenance workers undergoing troubleshooting or repairs, labels minimize the risk of operator error by clearly conveying warnings and operational instructions. Legible signage also allows you to seek effective preventive maintenance that improves the system’s performance and extends its lifespan.

Types of Labels Used in Solar Installations

While their specific wording and colors may vary depending on the jurisdiction, each type of solar label has a defined purpose that contributes to effective system operation. Whether it’s a simple wattage statistic or instructions for troubleshooting, these labels specify the guidelines necessary for standard performance.

PV Array Labels

Photovoltaic (PV) arrays require clear, durable labeling to identify connections and risks of your system. Any labels attached to these parts specify the amount of generated electricity from the array and provide additional details such as voltage settings or directions for disconnection. The National Electrical Code (NEC) mandates labels for PV arrays due to their benefits in safety during installation and troubleshooting.

Some PV array labels note the presence of high voltage or direct current (DC) wiring in the system. For example, there are labels that state “Warning! Solar Circuits May Be Energized During Daylight Hours.” This informs field personnel working near panels of potential hazards when the system disconnects in the daytime.

Disconnect Labels

Disconnect labels stick near shut-off points in solar energy systems. These labels support authorized personnel, so they can easily locate and operate switches to cut off power supply. Installed between the solar array and the inverter, these labels should be discernable to maintenance workers.

Disconnect labeling identifies the switch and provides clarity on how and when to use it. For multi-inverter systems, labels also indicate “Multiple AC Disconnects Present” to avoid confusion when turning off power. You will typically find these labels written as “PV System Disconnect Switch” or “AC Disconnect” as a standard for solar labeling.

Placards for Electrical Panels and Boxes

Electrical panels and combiner boxes store and distribute power in solar energy systems. These areas often house multiple high-voltage cables, circuit breakers, and inverters. Because these components hold high amounts of voltage, it’s important to distinguish them from other parts of the system.

Junction Box Placards

Junction boxes’ main role is to transfer and manage electrical currents throughout the grid. Placards placed on junction boxes commonly include notes about voltage, amperage, and enclosure ratings. To mitigate operator error or casual tampering, warnings such as “Caution! Electrical Panel—Authorized Personnel Only” deter unauthorized users from operating the component.

When operators label these boxes, they mitigate further risks and participate in preventative maintenance. For instance, many workers conduct thermal imagery testing and notice an overloading junction box due to the mishandling of electrical equipment. When explicitly labeled, however, maintenance workers can identify the parts to restore any distressing components before the system overheats.

Rapid Shutdown Labels

Rapid shutdown is an important feature in solar installations that allows systems to isolate voltages for safe handling during emergencies. This could include during natural disasters like a fire or when the system needs extensive repairs. Electrical equipment should include placards specifying its rapid shutdown capability.

Rapid shutdown labels include wording like “PV Array Equipped With Rapid Shutdown,” and some may incorporate standardized icons indicating the location of the rapid shutdown switch. These labels are especially valuable to fire crews and emergency responders unfamiliar with the system layout.

Hazard and Fire Safety Labels

Solar systems contain certain components that emit heat, involve high voltage, or contain flammable materials. Hazard safety labels warn workers against unintended exposure to these risks and act as a preventive measure that mitigates fire outbreaks.

Warning and Danger Labels

Danger signs are a type of label or placard used in solar installations used to provide information on conditions that pose serious hazards, such as energized circuits or live terminals. A standard example is “Danger! High Voltage—Risk of Shock or Injury.”

On the other hand, warning labels can also offer insight into conditions that may not necessarily lead to immediate injury but need attention. This could include arc faults from improperly installed wiring. Clear caution placards alert system operators and technicians to these risks.

Placards for Firefighter Access

Certain solar energy installations require specific information on display for firefighting purposes. These include DC conduit warning markers, tilt angles affecting light reflection, and battery storage enclosure details. Providing concise information reduces uncertainty during fire or rescue operations, allowing for quicker resolutions in times of crisis.

Labels for System Monitoring Components

Monitoring solar systems allows users to track the performance of their installations. However, without correct labels, these tools may be less effective in providing insights or fail to meet legal standards. Effective regulation allows you to manage your system to its fullest potential.

Data Logger Identification Labels

Data loggers evaluate system outputs and track performance metrics over time. For maintenance workers, labels guide these experts toward necessary components to connect or reset loggers without damaging expensive wiring. Labels also provide software configurations to make installations compatible with external diagnostic tools.

Network and Communication Labels

Locating communication cables used for Internet-of-Things (IoT) monitoring systems requires precise labeling. Solar energy systems often include modems, routers, and wiring that transmit performance signals across multiple locations. To complement these configurations, solar placards offer simple illustrations or instructions and resolve any issues regarding the network.

Weather-Resistant Labels That Endure Outdoor Conditions

Because of their consistent outdoor exposure, manufacturers use weather-resistant materials when designing their solar labels. This improves their longevity, especially in outdoor environments where factors like UV exposure, weathering, and harsh temperatures can test its durability.

UV Stable Labels

Solar installations sit exposed to sunlight, which means UV degradation is a common issue for labels. As a way to mitigate risk, UV-resistant labels prevent fading and peeling while maintaining legibility.

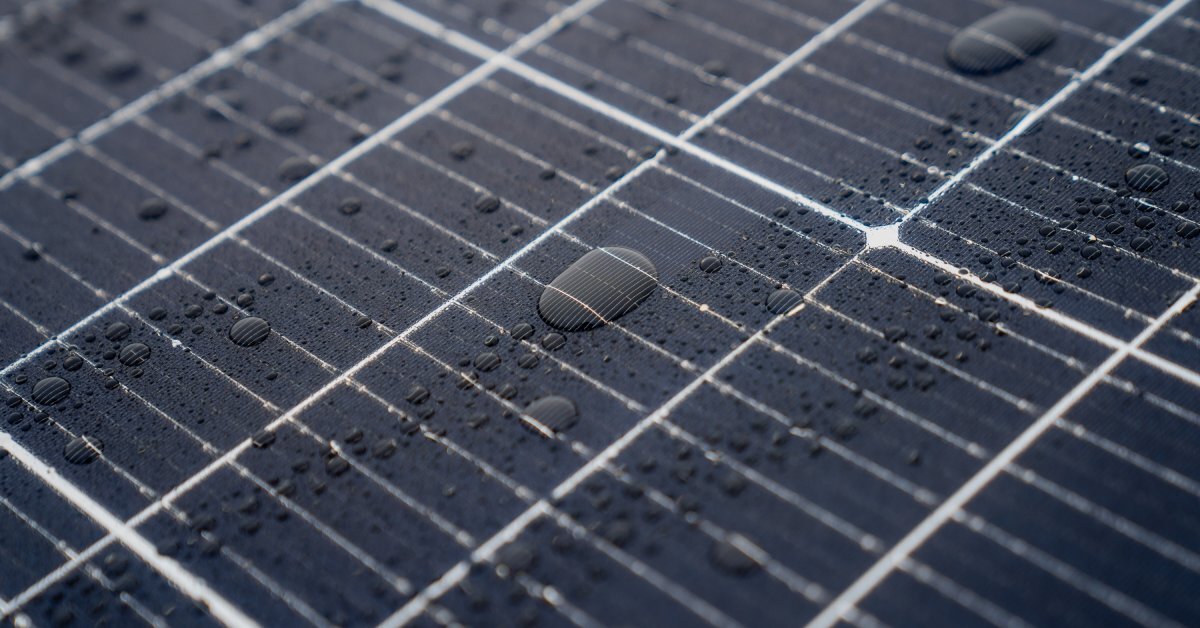

Water-Resistant Labels

Low-quality labels will typically fade due to rain or snow degrading the print or detaching from the surface. Electrical enclosures and roof-mounted solar panels benefit from labels made of waterproof materials like polyester or vinyl. As a sturdy resource for your solar installation, use valuable resources like durable, weather-resistant placards for your hazardous components.

If you’re planning to install a solar grid for your commercial business or need extra labels for your solar installation services, find your own solar placards and labels at Get Solar Labels! Our company offers a wide range of informative signage and sizes for your next solar installation project. Gather the necessary resources and tools you need to reap the benefits of solar.