Jun 26th 2024

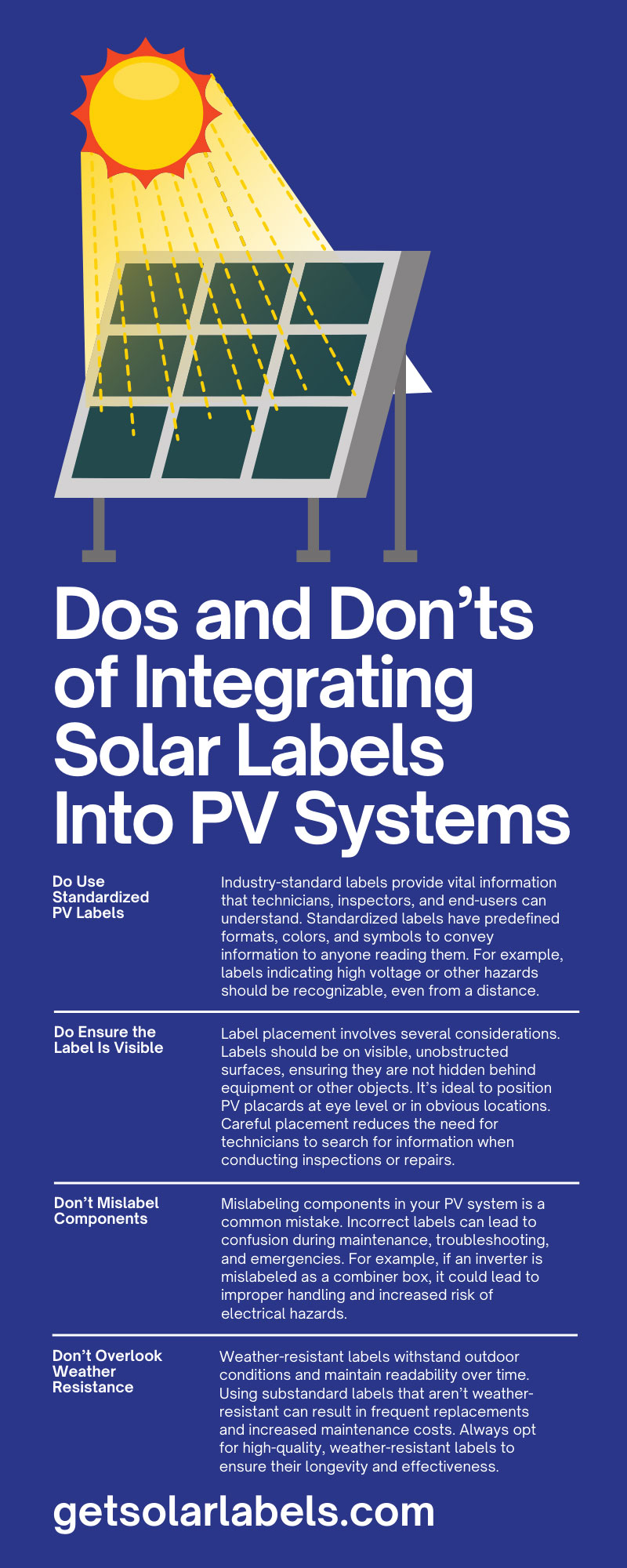

Dos and Don’ts of Integrating Solar Labels Into PV Systems

A photovoltaic (PV) system is a power system that converts sunlight into electricity by using photovoltaic cells. These cells are typically part of solar panels, which installers set up on rooftops, fields, or other locations to capture solar energy.

PV systems are intricate electrical appliances that require careful installation and maintenance. That’s why labeling is more than just a regulatory requirement; it’s essential for the safe and efficient operation of a solar power setup.

Missteps in this area can have severe consequences. If your PV system doesn’t have the right labels, continue reading the dos and don’ts of integrating solar labels to prevent safety hazards or system malfunctions.

The Dos of Integrating Solar Labels

Do Use Standardized PV Labels

The NEC (National Electric Code) provides comprehensive guidelines on labeling practices for electrical components like PV systems. Standardized placards are essential to improve the coherency of your solar power system.

Industry-standard labels provide vital information that technicians, inspectors, and end-users can understand. Standardized labels have predefined formats, colors, and symbols to convey information to anyone reading them. For example, labels indicating high voltage or other hazards should be recognizable, even from a distance.

In addition, using standardized labels simplifies the inspection process. Inspectors are familiar with these labels and can verify that the system complies with regulatory requirements once they see the labels. This speeds up the inspection process and reduces the likelihood of system delays or modifications. PV labels are not merely a best practice but a necessity.

Do Label Each Component Accurately

Outdated placard information or mislabeled components could be detrimental to maintenance workers and your PV system. According to the NEC, several components of PV systems require specific labels for safety, compliance, and maintenance purposes.

- Labels on PV modules provide important information such as voltage, current, power ratings, and manufacturing details.

- Labeling on disconnect switches or circuit breakers indicates their function and helps in identifying the correct isolation point for maintenance or emergency shutdown.

- Inverter labels convey details like AC and DC voltage ratings, maximum power output, safety instructions, and manufacturer information.

- Labels on combiner boxes identify the circuits they house and the disconnecting instructions for maintenance personnel.

- If the PV system includes energy storage batteries, they should have labels indicating voltage, capacity, chemical composition, and safety precautions.

- Labels near grounding and bonding points clarify their purpose and connection requirements.

- Various warning labels such as “DC Voltage,” “Arc Flash Hazard,” or “Electric Shock Risk” alert the reader of potential dangers.

This information lets technicians quickly identify system components and their specifications. This reduces system downtime, improves reliability, and supports diagnostics and repairs.

Do Ensure the Label Is Visible

The visibility of solar labels is crucial for easy identification. Labels must be easy to find and read by anyone who encounters the system. This minimizes the risk of accidents and guarantees critical information is always accessible.

Label placement involves several considerations. Labels should be on visible, unobstructed surfaces, ensuring they are not hidden behind equipment or other objects. It’s ideal to position PV placards at eye level or in obvious locations. Careful placement reduces the need for technicians to search for information when conducting inspections or repairs.

Do Keep Detailed Records of Maintenance

Maintenance records should encompass all inspections, repairs, and updates made to the PV system. They help you track performance over time and identify recurring issues. By keeping precise records, you can make informed decisions about upgrades or replacements that support the system’s longevity and reliability.

You might wonder how this relates to solar PV labels. Solar labels must reflect the most current system information. Thorough documentation provides the information you need when updating labels and reinforces safety during maintenance and inspection.

The Don’ts of Integrating Solar Labels

Don’t Mislabel Components

Mislabeling components in your PV system is a common mistake. Incorrect labels can lead to confusion during maintenance, troubleshooting, and emergencies. For example, if an inverter is mislabeled as a combiner box, it could lead to improper handling and increased risk of electrical hazards. Always label each component correctly with its function, and double-check your labels before finalizing them to avoid any errors.

Incorrect labeling can also lead to violations of regulatory standards. Non-compliance could result in legal repercussions and additional costs for re-labeling. Follow NEC guidelines by using permanent, weather-resistant solar PV labels that withstand the test of time.

Don’t Overlook Weather Resistance

Neglecting the importance of weather-resistant labels can compromise the durability of your PV system. Labels exposed to various environmental conditions like UV rays, rain, and wind can deteriorate quickly. When labels fade or peel off, they become unreadable and useless. This can lead to operational inefficiencies and safety risks.

Weather-resistant labels withstand outdoor conditions and maintain readability over time. Using substandard labels that aren’t weather-resistant can result in frequent replacements and increased maintenance costs. Always opt for high-quality, weather-resistant labels to ensure their longevity and effectiveness.

You must be aware of the environmental conditions your PV system will face, whether it’s extreme heat, bitter cold, heavy rainfall, or all of the above. Choosing durable and weather-resistant labels from the beginning will save you time, money, and hassle in the long run.

Don’t Neglect Routine Maintenance Procedures

Solar systems operate at optimal performance only with routine maintenance. Forgetting to update labels during maintenance or system upgrades is another costly mistake. Over time, components within your PV system may need replacing or upgrading. The labels must reflect the most current information to prevent confusion or errors during maintenance.

Double-check that the labels are accurate, visible, and readable. Disregarding this step can result in outdated labels that misinform technicians and compromise system integrity.

Integrating solar labels into PV systems demands adherence to these best practices. Sticking to the dos and avoiding the don’ts of integrating solar labels will help you maintain a secure and functional PV system.

Get Solar Labels can be part of ensuring the safety of your system. We provide NEC-approved solar placards that are customizable, weather-resistant, and easy to read. You won’t have to worry about mistakes after installing these high-quality labels on your property.